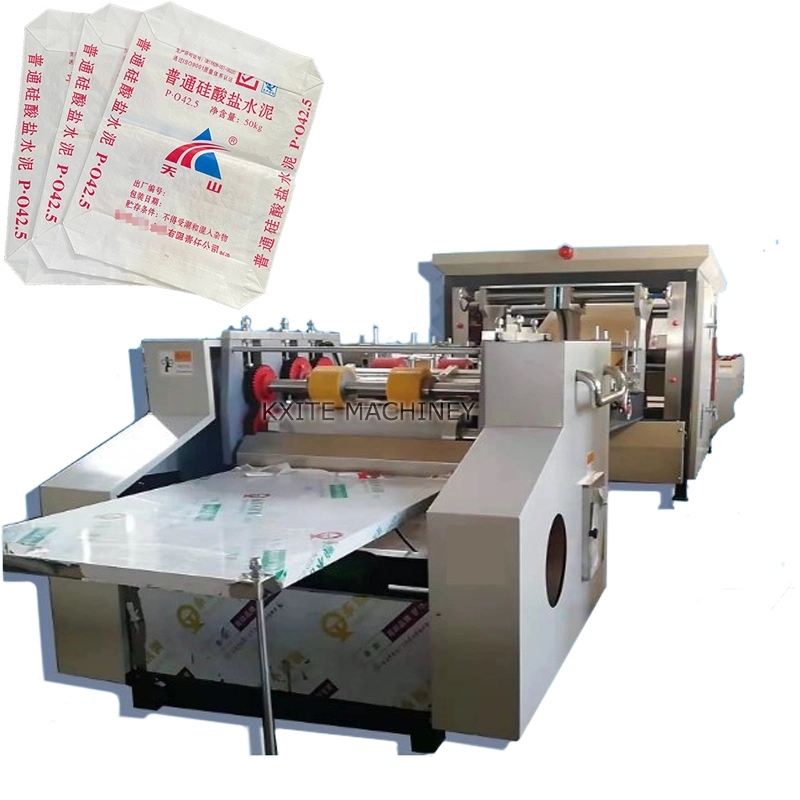

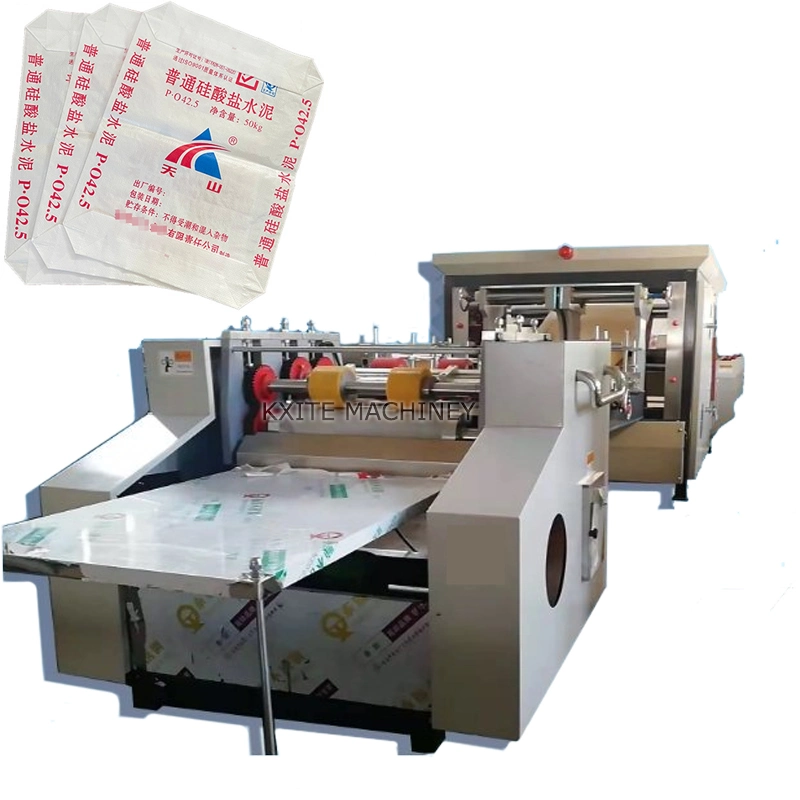

Multilayer Packaging Paper Bag Making Machine with Tension Controller

Overview Product Description Sample: Detailed Photos Product Parameters Why choose us? 1.New type PLC programming machin

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | KPM-650 |

| After-sales Service | 3year |

| Warranty | 1year |

| Product Line | 1 |

| Lines | 1 |

| Voltage | 380V |

| Seals Mode | Center Seals |

| Speed | High |

| Continuous-Rolled | No |

| Sealing & Cutting | Heat-Sealing Cold-Cutting |

| Layer | Double |

| Machine Type | Sealing Machine |

| Computerized | Computerized |

| Type | Paper Bag Making Machine |

| The Finished Bag Cylinder Width | 350-600mm, Free Adjustment |

| Bag Cylinder Side | Straight or Fold Side(Gusset Width Size:0-140mm) |

| The Layers of Finished Bag Cylinder | 1-4 Layers |

| Total Power | 26kw |

| Total Machine Weight | 15 Ton( Around) |

| The Machine Operators | 2 People |

| Control Method | Delta Servo Control System |

| Transport Package | Wooden Case |

| Specification | 17m*2.4 m*2.1m |

| Trademark | KOXTE |

| Origin | China Zhejiang |

| HS Code | 8477780000 |

| Production Capacity | 100sets/Year |

Product Description

| #1)The main units | |||||

| >>>Equipment control unit | |||||

| A.Electric cabinet | |||||

| B.Touch screen control(language:English and Chinese, chromatic screen) | |||||

| >>>Paper roll feeding unit | |||||

| A.Main structure | |||||

| 1.Paper roll feeding stands | |||||

| 2.Inflatable shaft:The core is made of 45# steel with hard chromium plating on the surface | |||||

| 3.Coil inertia removing stop device:Full automatic electronic control system | |||||

| 4.Automatic correcting deviation system | |||||

| B.Features | |||||

| 1.It make it easy to replace the paper roll | |||||

| 2.Avoiding paper waste due to inerior | |||||

| 3.Guaranting the paper on the fixed track | |||||

| >>>Printing unit | |||||

| A.1200 Four color flexo printing machine:1 set | |||||

| 1.The overall structure of the machine is casting | |||||

| 2.Frequency converter control | |||||

| 3.Speed can be random adjusted in the production in order to meet the requirement of synchronous operation. | |||||

| 4.Printing speed:20-70m per minute | |||||

| B.Main Parameter | |||||

| 1.Machine type:4/ 1200mm | |||||

| 2.Printing material:Paper | |||||

| 3.Maximum printing width:1100mm | |||||

| 4.Maximum printing length:300-1000mm | |||||

| 5.Printing speed:40-70m/min | |||||

| 6.Printing plate material thickness(including double-sided adhesive):3.64mm | |||||

| 7.The main machine adopts frequency converter to control speed, online synchronous printing | |||||

| 8.Heating and drying systyem | |||||

| >>>Bag tube forming unit | |||||

| A.Paper tube raphe gluing system | |||||

| 1.Glue-wheel, gluing roller, fractioning slice, glue box, position adjustable base etc. | |||||

| 2.Binder material:Glue | |||||

| 3.Pneumatic glue drawing | |||||

| 4.Glue recycling system | |||||

| B.Small rubber wheels with Screw brackets:10, to bend the paper into tube and press the raphe gluing position | |||||

| C.Paper bag gusset shaping plates:8, to shape the bag gusset ("M" paper bag side) | |||||

| D.Paper tube forming platform | |||||

| >>>Cutting and finished bag tube output unit | |||||

| A.Traction roller:Drag the paper in motion;2groups,4 big rubber wheels | |||||

| B.Wheel cutting knife:2,equip one + reserve one | |||||

| Knife tooth pitch:3.5mm | |||||

| Thickness of knife:3mm | |||||

| The width of knife:40mm | |||||

| Working life:About 300 thousand PCS bags cutting | |||||

| C.Working table to collect the finished bag cylinder |

Detailed Photos

Product Parameters

| The main parameters | |||||

| Production capacity | Normal 60-100 pcs/ min&80-150 pcs/min (speed is related with the length of bag and the gram weight of paper.), Frequency control Cutting speed | ||||

| The finished bag tube width | 350-630mm, free adjustment | ||||

| Bag tube side | Straight or "M" folding side(gusset width size:0-140mm) | ||||

| Bag tube length | 400-2000mm,Free adjusted, | ||||

| PLC programming | |||||

| Touch screen freely set the length | |||||

| Servo Motor Numerial control cutting | |||||

| The layers of finished bag tubes | Max 5 layers(1-5 layers confuguration for optional) | ||||

| Printing | In line& offline,flexo | ||||

| Printing Color No.s | Customzied,Normally 2 color,3 color,4 color,6 color for optional | ||||

| Total power | 26KW | ||||

| Total machine weight | 15 ton( around) | ||||

| Overall dimensions | Length17m×Width2.4 m× Height 2.1m | ||||

| The machine operators | 2 people | ||||

| Power supply condition | 380V,50Hz(we can add a transformer to fit your local electricity condition) | ||||

| Control method | DELTA servo control system | ||||

| Coiled material selecting indicators | 1.Roll material:Paper,PP/PE film,Paper Plastic lamianted Fabric etc. | ||||

| 2.Coiled material gram weight:70-120g/square meter | |||||

| 3.Diameter of paper roll≤Ф1250mm | |||||

| 4.Paper roll maximum width:1300mm | |||||

| 5.Paper roll inner core diameter:Slightly≥Ф75mm | |||||

1.New type PLC programming machine.

2.Easy operation.Touch screen computerized control.

3.Guaranteed quality.We have strictly quality control system from purchasing assembly part to installation and trial run.

4.Competive price.Our design principle is good quality but kick the dispensable part out.Also,10 years experience make us has enough resources to reduce the cost.

5.High speed and high production capacity

6.Technology support:We have our tech team and our boss have designed paper bag machine for more than 10 years.

7.We are factory.Our advantages are not only in good price.We will give you adequate convenience as your demand

Company Profile

Wenzhou Kxite Machinery Technology was established in 2010 and is committed to the development and production of environmentally friendly paper bag equipment. Provide customers with professional technical consultation, installation and commissioning, training and operation, and a whole set of professional service system.As a manufacturer of paper bag machines serving the world, we always put quality innovation first, from R&D design, parts procurement, assembly production, quality inspection and evaluation, sales to after-sales and other systems, to truly meet customer needsPrecise sales, think what you thinkBy inspecting the global paper bag production status, comprehensively considering the suggestions of printing and packaging industry veterans, according to the actual needs of different customers, we design and produce a variety of configuration models, allowing customers to choose flexibly.Excellent R&D managementWe have an excellent R&D design team and excellent management talents in the packaging industry. We fully understand the actual needs of the packaging industry, ensuring that every piece of equipment we manufacture can be affirmed by customers and create greater benefits.After-sale guaranteeProvide customers with comprehensive and timely after-sales service and a sense of service in the end.

| Sharp bottom paper bag machine | Window type paper bag machine | Flat Rope Handbag Paper Bag Machine |

| Double folding bottom paper bag machine | Square bottom paper bag machine | Round flat rope integrated paper bag machine |

| paper bag making machine | Round Rope Handbag Paper Bag Machine | UPS paper bag machine |

| Koxte paper bag making machine | Kxite paper bag making machine | Paper food bag making machine |

| Paige bag paper bag machine | Square bottom window paper bag machine | Siamese printing paper bag machine |

| Square bottom Siamese printing paper bag machine | Pointed bottom Siamese printing paper bag machine | KFC paper bag making machine |

FAQ

Pre-sales issues

How to answer technical guidance?

For some customers who need non-standard equipment, we will communicate with the company's relevant technical personnel according to the customer's specific requirements, taking into account the technical feasibility and production costs, and give customers solutions.

How to recommend products?

We can also provide non-standard equipment production and new product development services according to customer requirements. According to the customer's picture of the paper bag to be produced, the purpose of the product to be purchased, the environment, the purchase volume and other related conditions, we will recommend several cost-effective products for the customer to choose.

How to make a quotation?

Based on our company's research and development costs, production costs and customer purchases, we conduct calculations to determine the price of the product.

Problems in sale

About payment

After signing the contract, 30% of the total payment will be paid in advance, and the factory will accept the payment and pay the full amount of the machine for delivery.

About delivery time

About 90 working days after receiving the deposit (non-standard machine), the factory will re-decide whether to change the delivery date when the order is confirmed. The standard machine is generally within 60 working days after receiving the deposit.

Order tracking

After the customer places an order, our company will send professional personnel to track the order and regularly report the production progress to the customer. Customers can check the order status on the official website (delivery query).

Product testing

During the production process, our company will adopt strict inspection process to ensure product quality. Through internal inspection, we ensure that the components produced by our company meet the technical requirements; through external inspection, we ensure that the components produced by our company are not subject to quality problems; and then pass the whole machine inspection to ensure that the mechanical equipment meets the technical production requirements .

Product packaging

Before the product is shipped, it will be packed in a strict vacuum plus bottom tray (wooden tray or steel tray)

Product Transportation

Products are generally shipped from Ningbo Port, China to the destination port by sea.

After sales question

Shelf life/warranty period of the product

The product warranty period is generally one year, and our company provides lifetime maintenance services. If the machine has quality problems, our company will help the customer to solve it through the following ways: a. Send spare parts to the customer. b. Remotely assist customers in maintenance. c. Notify our agent company to send personnel to the customer's factory for maintenance. d. Our company directly dispatches relevant personnel to the customer's factory for maintenance.

About transportation damage

In the process of product transportation, if product damage occurs, it is determined that our product packaging and reinforcement work is not in place, and our company will bear the corresponding losses.

About machine maintenance

We will contact customers on a regular basis on how to maintain and maintain the machine. For domestic customers, we will have a master to provide on-site service.

Problems during use

If there is any problem in the process of using the product, the customer can directly call or send an email to our after-sales department (24-hour hotline). The personnel of our department will respond immediately and make a decision on the response measures within 24 hours.

Related Products

-

![Custom Logo Foldable Biodegradable 3-Ply E-Flute Corrugated Cardboard Kraft Paper Clothes Shoes Jewelry Packaging/ Shipping/ Packing Mailer Gift Carton Box]()

Custom Logo Foldable Biodegradable 3-Ply E-Flute Corrugated Cardboard Kraft Paper Clothes Shoes Jewelry Packaging/ Shipping/ Packing Mailer Gift Carton Box

-

![Customized Elegant Fancy Food Grade Chocolate Gift Retail Magnetic Closure Perfume Cosmetic Pakcaging Paper Flip Box with Plastic Insert]()

Customized Elegant Fancy Food Grade Chocolate Gift Retail Magnetic Closure Perfume Cosmetic Pakcaging Paper Flip Box with Plastic Insert

-

![Luxury Popular Cardboard Hair Care Extension Comb Packaging Lid and Base Box]()

Luxury Popular Cardboard Hair Care Extension Comb Packaging Lid and Base Box

-

![Customized Drawstring Gift Silk Satin Pouch, Hair Extension Packaging Black Satin Bag with Logo Printing]()

Customized Drawstring Gift Silk Satin Pouch, Hair Extension Packaging Black Satin Bag with Logo Printing